85072 Eichstätt

Kontakt

Telefon: +49 (0) 8421 / 98 89-79

Telefax: +49 (0) 8421 / 98 89-88

E-Mail: mkb@m-k-b.de

Aluminium

Wiederverwertbare Werkstoffe für nachhaltige Konstruktionen

Aluminium-Silizium-Legierungen ermöglichen durch ihre hervorragenden Fließeigenschaften und gute Zerspanbarkeit die Herstellung von komplexen, feingliedrigen Bauteilen, die genau definierte Anforderungen zu erfüllen haben.

Durch Zulegieren von Si und Mg können variable Festigkeitseigenschaften, oft eine hohe Dehnungs- sowie Schlagzähigkeit erzielt werden. Die verwendeten Primäraluminiumlegierungen sind korrosionsbeständig.

Aluminium-Zink-Legierungen (hier: AlZn10Si8Mg) finden ihren Einsatz, wenn hohe Festigkeiten verlangt werden. Durch Ihren selbstaushärtenden Charakter regenerieren sie sich nach Überbelastungen.

Einsatzbereiche

Gussteile aus einer Aluminium-Legierung eignen sich vor allem für komplizierte, druckdichte, schwingungs- und schlagfeste Konstruktionselemente.

Entsprechend werden sie vielfältig eingesetzt:

- im Maschinen-, Kraftfahrzeug- und Motorenbau

- im Haushaltsgerätebau

- in der Wehrtechnik

- in der Elektrotechnik

- in der Bahntechnik

- in der Windkrafttechnik

- in der Umwelttechnik

- in der E-Mobilität

Legierungen

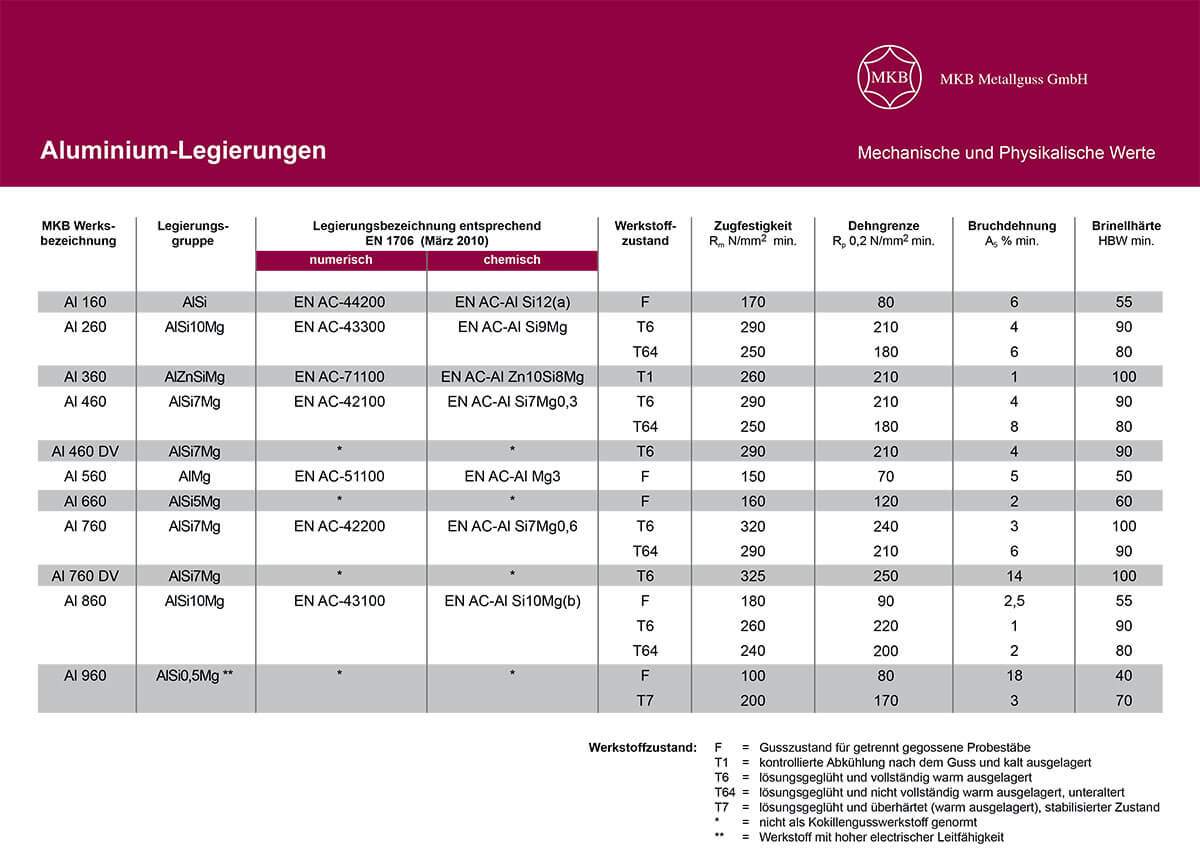

EN AC-Al Si12 ist eine eutektische Legierung mit ausgezeichnetem Formfüllungsvermögen, hoher Warmrissbeständigkeit und ausgezeichneten Gießeigenschaften bei hoher chemischer Beständigkeit. Sie ist ausgezeichnet schweißbar und verfügt über mittleren Festigkeitseigenschaften, hohe Bruchdehnung und eine gute Schlagzähigkeit. Diese Legierung ist nicht warm aushärtbar. |

EN AC-Al Si9Mg / EN AC-Al Si10MG sind eine der wichtigsten aushärtbaren AlSi-Gusslegierungen. Sie ist eine naheutektische Legierung mit ausgezeichneten Gießeigenschaften, guter Warmrissbeständigkeit, guter Spanbarkeit und hoher chemischer Beständigkeit. Zudem zeichnet sich diesen Werkstoff durch hohe Festigkeitswerte nach der Wärmebehandlung sowie eine ausgezeichnete Schweißbarkeit und gute Spanbarkeit aus. |

EN AC-Al Si7Mg0,3 gehört auch zu den wichtigen untereutektischen AlSi-Gusslegierungen mit mäßigem Fließvermögen. Sie ist warm aushärtbar. Mit ihr sind Konstruktionen hoher Festigkeit herstellbar bei noch bemerkenswerter Zähigkeit und Dehnbarkeit. Sie besitzt eine sehr gute Korrosionsbeständigkeit und damit hohen Widerstand gegen chemische Angriffe. Außerdem hat diese Legierung eine gute Span- und Schweißbarkeit. |

EN AC-AlZn10Si8Mg ist eine selbstaushärtende Gusslegierung mit sehr gutem Fließvermögen. Aufgrund des hohen Zinkgehaltes ist die Korrosionsbeständigkeit stark herabgesetzt. Nicht für Gussteile mit schwingender oder schlagender Beanspruchung geeignet, bzw. für Gussteile, die Biege- oder Scherkräfte aufnehmen müssen oder eine bestimmte Zähigkeit erfordern. Ein plötzlich eintretender Sprödbruch ist nicht auszuschließen. Die Festigkeit tritt durch eine 10-tägige Lagerung bei Raumtemperatur ein. Der Hauptvorteil dieser Legierung liegt in der Einsparung der Wärmebehandlungskosten. Daneben ist sie ausgezeichnet span- und schweißbar. |