85072 Eichstätt

Kontakt

Telefon: +49 (0) 8421 / 98 89-79

Telefax: +49 (0) 8421 / 98 89-88

E-Mail: mkb@m-k-b.de

Kokillenguss

einbaufertige Präzisionsteile in kürzester Zeit

Kokillenguss-Formen fertigen wir in höchster Präzision, mit anwenderfertigen Oberflächen und exakt in der Qualität, die Sie benötigen. Ohne große Investitionen. In kleinen und großen Stückzahlen. Und mit nachhaltigen Prozessen für einen möglichst geringen CO2-Fußabdruck.

Darauf können Sie sich bei MKB als Partner für Kokillenguss verlassen

- persönliche Beratung

- konsistente Qualität

- hochwertiger Materialeinsatz

- Produktion nach Vorgabe

- nach EN 1982 und EN 1706

Kokillenguss in höchster Legierungsqualität – seit 1965

Mit passgenauen Metallqualitäten, hoher Flexibilität und jahrzehntelanger Erfahrung unterstützen wir Sie an unsere 4 internationalen Produktionsstandorten dabei Ihre Produktionsprozesse zu optimieren. Kokillengussteile nach Maß und in höchster Legierungsqualität erhalten Sie einbaufertig bearbeitet, montiert oder beschichtet – und immer 100% freigegeben in Germany.

Hierfür arbeiten wir konsequent an der Optimierung unserer Prozesse und an weiteren Lösungen zur CO2-Reduktion. Schon heute generieren wir eigenen Strom mit Photovoltaik. Und erarbeiten individuelle Konzepte für eine Lieferung der kurzen Wege. Bei gleichbleibend hoher Qualität helfen wir Ihnen so, klimagerechter zu produzieren und Kosten zu senken. Ab 25 Stück pro Los.

Kokillengießverfahren von MKB – Überlegen im Vergleich. Überzeugend im Guss.

Der Kokillenguss ist ein Gießverfahren, bei dem die Schmelze in eine metallische Dauerform gegossen wird. Diese metallische Dauerform wird als Kokille bezeichnet.

Werkstoffe wie Reinkupfer, Kupfer-Chrom- Legierungen, Kupfer-Aluminium-Legierungen, Messinge sowie Aluminiumlegierungen werden bei MKB vergossen. Durch die im Kokillengießverfahren sehr schnelle Abkühlgeschwindigkeit eignet sich dieses Verfahren sowohl für Klein- als auch mittelgroße Serien.

Hohe Oberflächengüte sowie Maßgenauigkeit zeichnen dieses Verfahren aus. Eine mechanische Nacharbeit wie Drehen oder Fräsen ist in vielen Anwendungsbereichen nicht nötig.

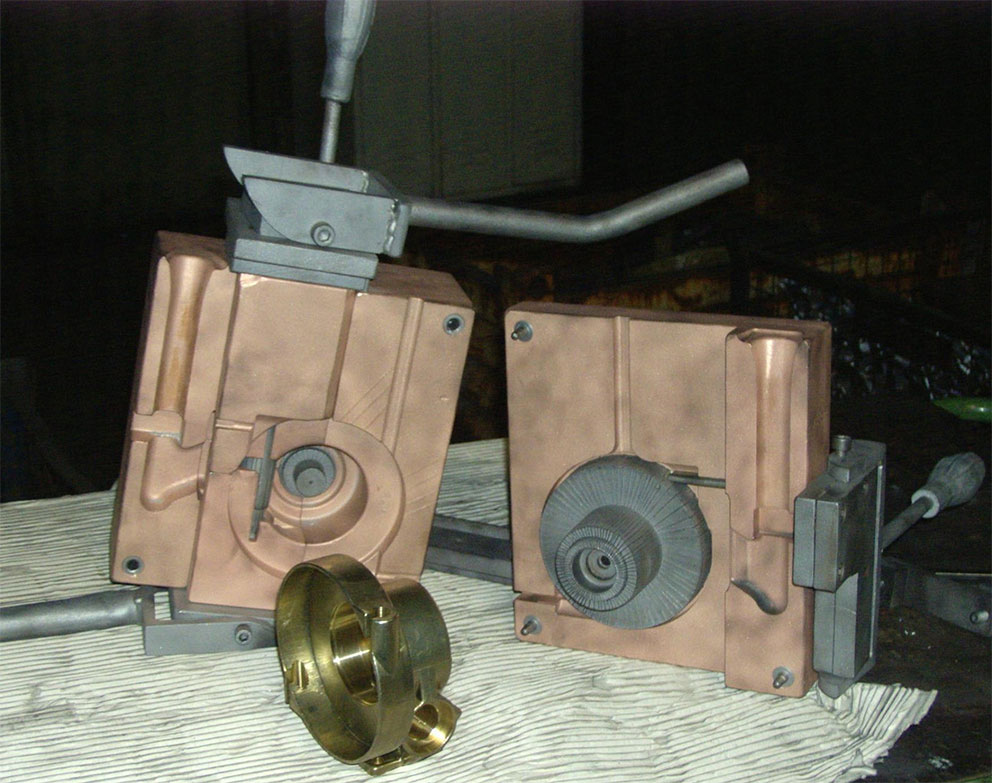

Kokillen aus Stahl oder Kupferlegierung für einen sicheren und präzisen Gießprozess

Zur Produktion der Gussteile kommen Kokillen aus Stahl sowie Kupferlegierungen zum Einsatz.

Diese Kokillen werden durch Einsätze aus Stahl, aber auch Sandkerne ergänzt. Dies ermöglicht den Guss selbst komplexester Bauteile und Geometrien.

Diese im eigenen Werkzeugbau gefertigten Kokillen überzeugen durch eine sehr hohe Wiederholungsgenauigkeit an Ihren Gussteilen.

Verschieden Verfahren der Kokillengießtechnik passgenau für Material und Zweck

Ausgerichtet nach den technischen und wirtschaftlichen Bedürfnissen von Maßhaltigkeit und Mechanik, Güte der Oberflächenbeschaffenheit und nicht zuletzt der Stückzahl bieten sich verschiedene Verfahren bei der Kokillengießtechnk an.

Beim Schwerkraftkokillengießverfahren wird die Kokille allein durch die Schwerkraft über das Angusssystem mit Metall gefüllt. Eine Kippbewegung wärdend des Füllvorgangs verbessert die Gussqualität.

Dass Niederdruck-Kokillengießverfahren wiederum sorgt für eine ruhige Formfüllung. Hierbei wird die Form von unten mittels Druck befüllt. Das Material steigt in der Kokille.

Für Serienfertigung in u.a. Automobilindustrie, Maschinenbau und Elektrotechnik

Verwendungszweck findet das Kokillengießverfahren vor allem bei klein- und mittelgroße Serien. Aber auch größere Stückzahlen können durchaus im Kokillengießverfahren wirtschaftlich produziert werden. Wir bieten Ihnen den dem Sandguss in vielerlei Hinsicht überlegenen Kokillenguss im Rohguss in hoher Präzision von bester reproduzierbarer Qualität und ausgeprägter Festigkeit für noch mehr Wirtschaftlichkeit bei der Fertigung.

Kokillenguss von MKB - Effizienz und Verantwortung von Anfang an

Flache Hierarchien und schlanke Prozesse stellen von Anfang an eine transparente und zielorientierte Kommunikation sicher. Dringliche Anfragen können wir als mittelständischer Betrieb flexibel priorisieren. Damit wir unseren hohen Anspruch an Qualität und Effizienz auch zukünftig gerecht werden, setzen wir schon heute auf das kontinuierliche Testing und Audits unserer Partner, die Überprüfung mechanischer Eigenschaften unserer Kokillenguss-Teile durch menschliche Analyse – und auf die Ausbildung zukünftiger Talente.

Datenanlieferung

Ihren 3D-Datensatz oder Ihre Zeichnung können Sie uns ganz einfach per E-Mail als STEP-Datei, jpg oder PDF zusenden. Binnen weniger Tagen nach Erhalt melden wir uns persönlich bei Ihnen, um das weitere Vorgehen zu besprechen.

Hier geht’s zum Upload

Häufig gestellte Fragen:

Wieso ist der Kokillenguss ein kostengünstiges Gießverfahren?

Die Werkzeugkosten beim Kokillenguss sind im Vergleich zu anderen Gussverfahren sehr gering. Zudem ist keine nachträgliche mechanische Bearbeitung der Oberflächen nötig: Die Gusshaut ist anwenderfertig. Insbesondere bei Gussformen aus Aluminium können meist noch Gewicht und Material eingespart werden. Dadurch sind zum Teil sehr hohe Kosteneinsparungen möglich – ohne Qualitätsverlust.

Für welche Produkte eignet sich der Kokillenguss besonders gut?

Beim Kokillenguss werden alle Nichteisen-Metalle (NE-Metalle) vergossen. Dazu zählen Kupfer. Aluminium, Zink, Messing und Blei. Als Partner der Elektro- und Bahnindustrie vergießen wir hauptsächlich Produkte aus reinem Kupfer (Cu, CuCr) und Kupferlegierungen (Messing, Aluminiumbronze) nach EN 1982 sowie Aluminium-Legierungen (AlSi, AlZn) nach EN 1706.

Welche Toleranzen können im Kokillenguss erreicht werden?

Welche Toleranzen erreicht werden können, ist abhängig von dem genauen Längenmaß. In der Regel können beim Kokillenguss können meist sehr geringe sowie bessere Formtoleranzen als beim Sandguss erreicht werden. Unsere Toleranztabelle gibt Ihnen einen fundierten Überblick. Diese Tabelle übernimmt keine Gewähr bei Maßabweichungen.

Kokillenguss im Vergleich

vs. Schweißkonstruktionen:

- oft kann auf eine mechanische Bearbeitung verzichtet werden, da konturnah gefertigt wird

- Kosteneinsparungen ab einer wirtschaftlichen Stückzahl

- vielfältige Designs, wirtschaftlich umsetzbar

- vorgegossene Bohrungen (Rundloch-, Langlochvarianten)

- Materialeinsparungen

- steifere Konstruktion durch kostengünstige Versteifungsrippen und Radien

- die „Schwachstelle Schweißnaht“ entfällt

- Widerstände im Stromfluss an der Schweißnaht fallen weg

Kokillenguss im Vergleich

vs. Feinguss:

- oft sind die kostspieligen engen Toleranzen des Feingusses nicht für die Anwendung erforderlich,

der Kokillenguss hat hier Vorteile - geringere Werkzeugkosten

- kürzere Lieferzeiten

Kokillenguss im Vergleich

vs. Vollbearbeitung:

- gravierende Kosteneinsparungen ab einer wirtschaftlichen Losgröße

- keine hohen Materialverluste

- geringe Laufzeiten der Bearbeitungsmaschinen

Kokillenguss im Vergleich

vs. Sandguss:

- bessere elektrische Leitfähigkeit bei Kupferlegierungen

- kostengünstigeres Fertigungsverfahren

- engerer Toleranzen und bessere Oberflächen

- das Risiko der Gasaufnahme der Schmelze aus dem Formstoff entfällt

- oft ist eine mechanische Bearbeitung nicht mehr nötig

Kokillenguss im Vergleich

vs. Druckguss:

- kürzere Lieferzeiten

- deutlich geringere Werkzeugkosten

- auch kleine Losgrößen sind wirtschaftlich zu fertigen

- Schweißbarkeit bei Aluminiumlegierungen

- Hinterschneidungen und Hohlräume sind möglich

Rohguss

Auch Rohguss kann präzise sein

Schon im Rohguss ist unser Kokillengießverfahren vielen anderen Formverfahren überlegen,

insbesondere in Bezug auf Präzision, Festigkeit und Wirtschaftlichkeit:

- sämtliche Rohgussteile werden mit hoher Genauigkeit nach DIN EN ISO 8062-3 hergestellt

- kupferhaltige Legierungen werden nach EN 1982 bzw. als MKB-Sonderlegierung vergossen

- Aluminiumlegierungen werden nach EN 1706 vergossen

- eine permanente chargenbezogene Überwachung mittels Spektralanalyse garantiert die genaue Einhaltung der Norm-Werte und der geforderten Festigkeitswerte

- hohe Präzision gepaart mit langjähriger Erfahrung bürgt für dauerhaft

- reproduzierbare Qualität

- durch intensive Beratung schon in der Konstruktionsphase

Kontakt

Tobias Koderer

Leiter Vertrieb / Marketing

Jetzt unverbindlich anfragen und beraten lassen.

Kontakt +49 (0) 8421 - 98 89 89

E-Mail: mkb@m-k-b.de

Terminvereinbarung

Gerne beraten wir Sie - vereinbaren Sie einen Termin