Mechanical and plant engineering

For a machine’s lifetime

Die casting is ideal for use in mechanical and plant engineering

The excellent properties of the materials used ensure economical operation and high stability. The desired mechanical properties for almost all requirement profiles can be achieved by targeted variation of the alloy elements and excellent casting technique.

Filling/labelling equipment, conveyor technology

The tensile strength values of some copper-aluminium alloys and also copper-zinc alloys (special brass) reach or even exceed the levels of common steel types. These properties are largely retained even at higher temperatures up to approx. 300 °C.

Compared to many cast iron materials, the almost constant toughness of copper-aluminium alloys and copper-zinc alloys proves to be particularly advantageous at low temperatures down to -200 °C. Added to this are the good sliding, bearing and emergency running properties.

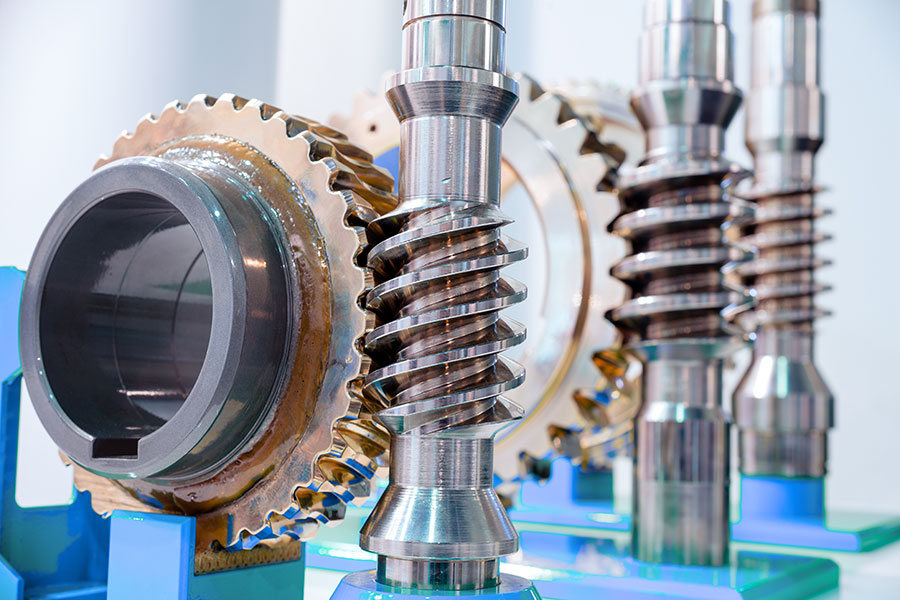

Drive Technology

Liquids, gases and solids (granulates) are transported through technical plants. To control the flow rate, reliable actuators are important in the valves used. We manufacture components made of aluminium bronze, which can have a positive influence on the maintenance cycles of the plants due to their long service life. In particular, aluminium bronze in combination with other materials (e.g. steel) allows a long actuator service life.