Brass

Recyclable materials for sustainable designs

Copper-zinc alloys can be individually adapted to diverse areas of application. By adding Al, Mn, Si, Fe or Pb alloy elements, important properties can be emphasised for each application.

Good casting properties of the material combined with our many years of experience in the design of die / core insert combinations, enable thin-walled and complex geometries.

Strength comparable to conventional steels, corrosion resistance - particularly against weather influences, saltwater resistance and high wear resistance - and good machinability give the designer an inexpensive alternative for a wide range of applications.

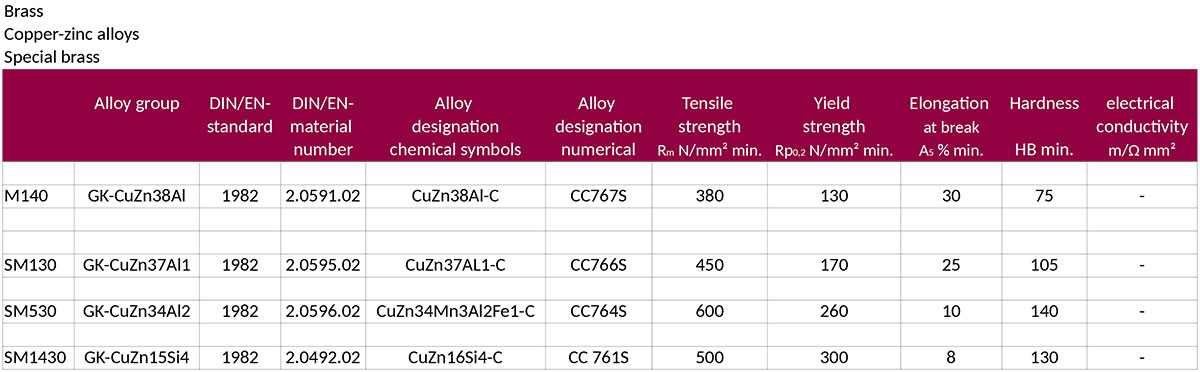

In particular, CuZn38Al-C, CuZn37Al1-C, CuZn34Mn3Al2Fe1-C and CuZn16Si4-C have proven themselves as casting materials.

Copper-zinc alloys are not harmful to health, and their surfaces have an antimicrobial effect.

Areas of application

Castings made of copper-zinc alloys can be used in a variety of ways:

- In mechanical and plant engineering, e.g. conveyor technology, ventilation technology, for tool, power and printing machines, in drive technology, as well as in robotics and automation, and much more.

- In special machine and plant engineering as a bevel gear segment, gear and bevel gear, or worm gears.

- In pump construction as pump, suction and pressure housings, for bucket wheels, segment sockets and stage casings, and much more.

- In medical technology for milling arms, pipe bends or medical devices.

Alloys

We offer our customers individual copper-zinc alloys, which we develop specifically according to requirements.

By alloying the elements, mechanical properties for almost all possible applications can be realised.

We would be happy to advise you on choosing the optimal material.