Copper

Recyclable materials for sustainable constructions

COPPER

The highest possible electrical conductivity and thermal conductivity can be achieved in gravity die casting using the appropriate copper quality. The purity of the copper in combination with the manufacturing process essentially influences the conductivity values. Electric currents are thus transmitted with extremely low resistance in pure copper castings. In addition, copper is very corrosion-resistant.

Complex geometries are produced close to the design contours by using core inserts in the gravity casting die and reduce downstream activities in mechanical processing. We are happy to help you achieve a cast-ready design.

COPPER CHROME

CuCr1 casts are characterised by the combination of high strength, and high electricity and heat conductivity. Electrode holders and mechanically loaded contacts are often made from this material. It is also great for further processing, including mechanical polishing, galvanisation, and dip tinning.

Areas of application

Designs produced using copper die casting can be found wherever electrical currents flow.

As contact carriers, short-circuit rings, ground/earth contacts, contact fingers, high-voltage switch parts, electrode arms and much more, they are used in various fields:

- electrical engineering

- energy supply

- converter construction

- transformer construction

- railway technology / overhead line construction / catenary systems

- welding electrodes

- e-mobility

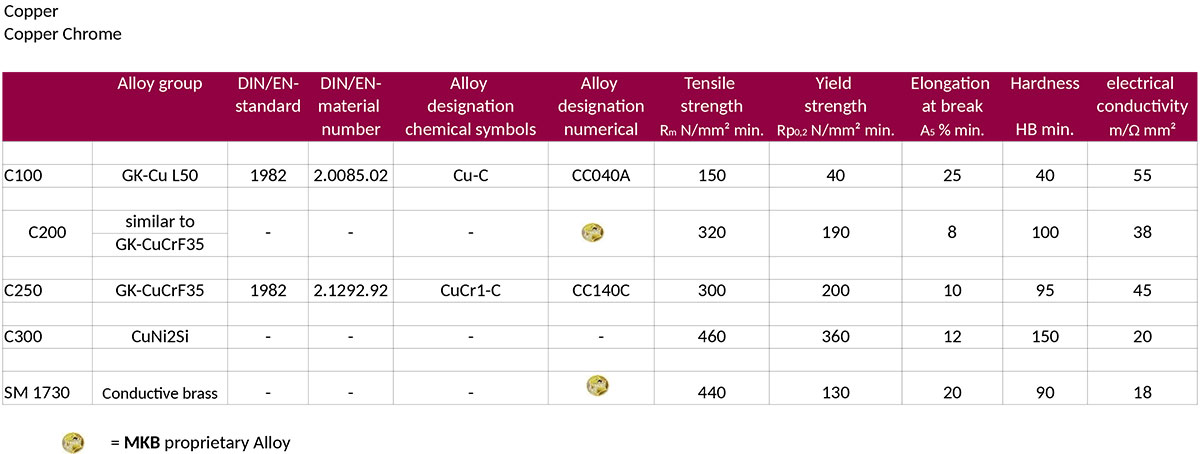

Alloys

- Cu-C is highly conductive and offers a wide range of applications. When silver-plated it has even higher conductivity, especially on the contact surfaces.

- CuCr1 is a chrome-alloyed copper material that is particularly hard and strong. Nevertheless, it also has good electrical conductivity.