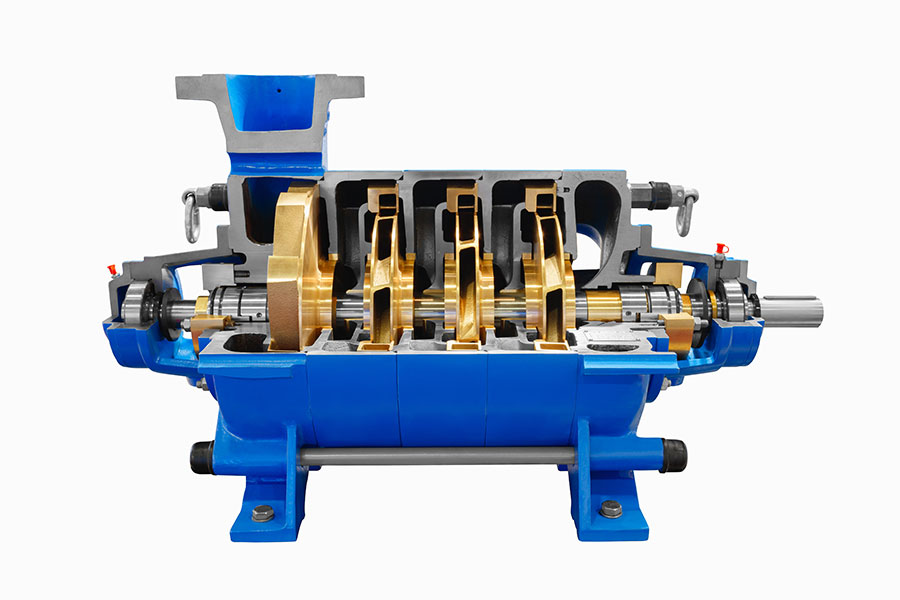

Pump and underwater technology

High-flying, even in the deep

Components made of copper-aluminium alloys,

which are produced by die casting, have extensive corrosion resistance, even in aggressive gaseous and liquid media. It is no wonder they are preferred by designers in the pump construction and underwater technology sectors.

A balanced Al-Ni ratio ensures largely high corrosion resistance, even in

- slightly acidic to slightly alkaline salt solutions (sulphite and bleach lyes, potash salt solutions)

- industrial effluents

- saltwater and organic media (including acetic acid)

- reduced and slightly oxidising mineral acids (diluted e.g. 10% hydrochloric acid, hydrofluoric acid, 1% phosphoric acid and especially concentrated sulphuric acid), and

- aggressive industrial atmospheres close to the sea or containing sulphur dioxide.

CuAl10Ni3Fe2-C, CuAl10Fe5Ni5-C and CuAl11Fe6Ni6-C are especially well-proven as casting materials.

Furthermore, these parts are characterised by high mechanical strength and durability. If other properties are required, such as good machinability and the possibility of galvanic plating, copper-zinc alloys (special brass) provide the perfect answer.